AllScan Cf-252

Cement Production

The AllScan CF-252 PGNAA analyser combines state-of-the-art technology with ground-breaking spectra modelling and powerful statistical analysis in provision of elemental analysis in real time. Installed on a conveyor belt, the AllScan delivers accurate, minute-by-minute elemental analysis and reporting of the chemical composition of bulk materials and key process parameters.

AllScan

Cement Analyser

Accurate real time data on the composition of raw material feed streams before stockpiles or raw mills increases product quality and contributes significantly to reduced production costs. Since its market introduction in the 1980s PGNA Analysis is widely acknowledged as the by far superior on-line analysis technology for cement process quality optimization. Documented by close to a thousand installations, the documented analytical performance coupled with the very fast control response means that PGNAA has grown to become the leading on-line quality control concept in the cement industry. Today, almost every new green field cement project lay-out includes one or more PGNA Analysers.

Other on-line analysis technologies applied in cement, such as IR/NIR/-FTIR and XRF/EDXRF analyses the material/sample surface only, while the penetrating concept of PGNAA measures the entire product stream. RTI’s AllScan analyser has been developed with particular emphasis to address practical analytical challenges experienced with less advanced analysers. Best in class robustness of the applied calibration model as well as high tolerance towards material depth variations and effects from layering on the belt conveyor through the analyser are some of the most notable benefits of AllScan. Very low installation costs and moisture analysis capability always included with no added costs makes the Total Cost of Ownership (TCO) for a typical cement installation the lowest on the market.

Theory of Operation

At the heart of the AllScan is PGNAA – prompt gamma neutron activation analysis. Material on the conveyor is bombarded with neutrons emitted from radioactive isotope.

When neutrons collide with an element in the material, gamma rays are emitted with a specific energy unique to that element – in effect, creating chemical signature for that element. The greater the amount of an element in the material the greater the number of gamma rays emitted with the corresponding specific energy. By measuring the specific energy of the gamma rays that are emitted and the counts of gamma rays, an accurate analysis of the chemistry of the material is generated on a second-by-second basis.

Measurement

Parameters

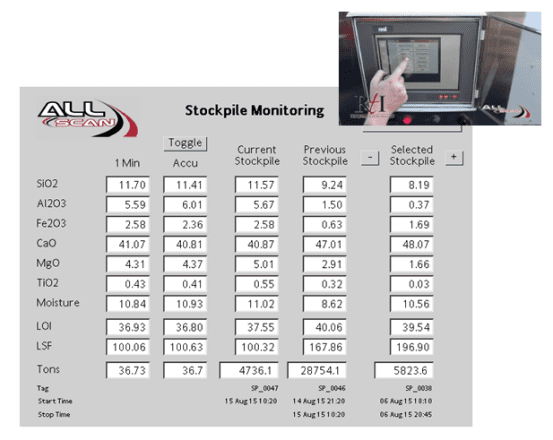

The AllScan Online Cement PGNAA Analyser measures and reports analytical data of relevance for cement production, such as: SiO2, Al2O3, Fe2O3, CaO, MgO, Na2O, K2O, S etc + Moisture as well as customer-defined derived cement chemistry modules like LSF, KH, SIM, ALM etc. Accessible from the touch screen integrated in the control cabinet or utilizing various available interface options, the AllCement user interface software presents:

- Configuration data

- Status information

- Last 1-min analysis values

- Tonnage weighted rolling averages

- Configurable trends

- Current accumulated pile

- Previous accumulated pile

- Data from selected piles

Stockpile and

Quarry Management

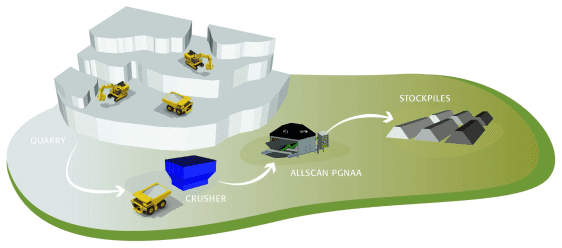

The use of AllScan in Quarry and Stockpile management applications at cement plants facilitates significant improvements in pre-blending performance through:

- Optimized utilization of quarry materials

- Homogenized building of the stockpiles to desired target chemistry with minimum variations

In the cement Stockpile application, the AllScan® is typically installed on a conveyor section between crusher(s) and stockpile(s). The AllScan® continuously reports the elemental composition of the conveyed material. The data obtained is used to keep track of the pile build-up and may optionally via 3rd party optimizing software be used to direct haul trucks to different sections of the quarry to best exploit the quarry over time as well as to optimize the quarry equipment utilization.

Stockpile and

Quarry Management

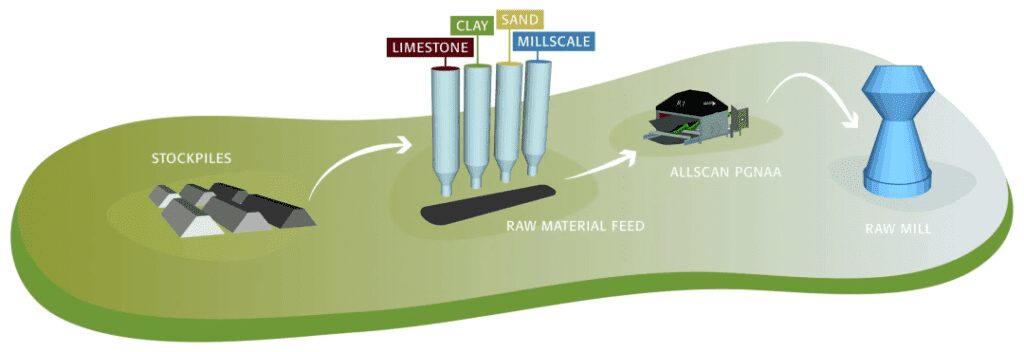

Another important cement plant application for AllScan® is to provide fast on-line analytical data for a Raw Mill quality control application. Here the analyser is placed on a conveyor belt section downstream of the feeders and upstream of the raw mill.

The on-line analytical data by AllScan® is the essential basis for 3rd party software QC optimizing schemes, which is applied for:

- Green field projects facilitates smaller and therefore less expensive homogenizing silo systems

- Existing plants may be the ‘repair tool’ for poor functioning blending control of feed to raw mill.

Both case examples mean significantly reduced variability in the raw mix product from the mill, and ultimately the kiln feed. Consistent kiln feed chemistry in turn leads to better quality clinker, lower fuel consumption per ton of clinker produced, reduced refractory costs etc.

A less frequently applied application, however, increasingly demanded from the market is to install a PGNA Analyser to monitor the delivery of coal/lignite to cement plants. In particular where, poor quality lignite or varying coal qualities from a range of different suppliers are received the installation of AllScan may provide significant quality improvements by close monitoring of the ash contents and percentage of the incoming coal/lignite.

AllScan offers easy connectivity to cement plant control systems:

- Application data from the AllScan are seamlessly transferred to the plant control system and is typically interfaced to 3rd party cement QC software to optimize quarry operations, stockpiling and raw mix proportioning

- AllScan interfaces by means of applicable electrical standards and communication protocols with well-known DCS & PLC type Plant Control Systems as well as QC optimization software from leading suppliers of cement specific quality control software.